Insulated Garden Rooms - New Bespoke Options Available

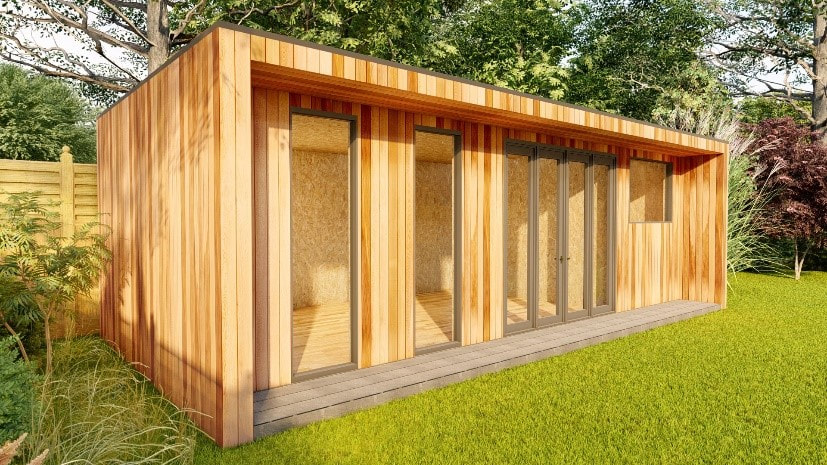

We are happy to introduce a new outdoor garden room solution. If you are looking for extra space with regards to an office building, summerhouse, outdoor gym, guest room, kids area etc then these efficient garden buildings may be just what you are looking for. The buildings are constructed using an insulated panel system and can be cladded internally and externally with woods/materials of your choice. All to current building regulations. We have tried to keep it all very simple with four basic building desings. All you then need to do is decide on the size of the building, what you would like to have it cladded in (see examples below), what doors and windows you require and where the electrics need to go. Most of the designs are manufactured under 2.5m which is within permitted planning height requirements for a garden building. (See you local planning portal for more details on permitted development).

Choose from a standard design or bespoke

Benefits of an insulated garden room

Here are some of the benefits our customers have found:

- Building kits supplied flatpack and ready to assemble. Typically reducing labour time and costs by up to 60-70% compared to traditional construction methods

- Significantly more structurally rigid than timber frame

- Highly thermally efficient and our innovative manufacturing and construction processes mean we can achieve up to 90% less waste on-site

- Average size kits are erected in as little as a day (Excluding cladding, Roofing, Windows, and Doors)

- Naturally sound absorbing benefits

- Airtight performance

Materials in our SIP building

All of our buildings are made from Structural Insulated Panels. These are made from a layer of Polyurethane that is injected between two sheets of 11mm OSB3 Board. These highly versatile panels form the floor, walls, and roof giving you an incredibly strong structure with exceptional thermal performance. Our Panel Sizes: 72mm, 97mm, 122mm, 147mm, 172mm and 200mm

Energy Efficient Eco Buildings

Comfortable space throughout the seasons. Our entire range of buildings are highly insulated and designed to be energy efficient.

Available in Bare Kits or Full Kits

|

Standard items:

Optional Items:

|

|

Standard Models Available

We have over 20 Space Designs for you to choose from and if these are still not what you require you can let us see your design requirements and give you a quote.

Space One Design

Space Two Design

Space Three Design

Space Four Design

Different uses for a garden room

These versatile buildings can be used for so many different purposes dependent on the personal requirements of the client. Please see some of the options below:

GALLERY OF RECENT GARDEN ROOMS

Outdoor classroom

Summerhouse, chillout room

Garden Office

Outdoor Gym

What are Sips?

Structural Insulated Panels (SIPS) are an advanced method of construction offering excellent thermal performance, light weight structural strength, and time and cost saving benefits over traditional construction methods. SIPs combine several components of conventional building, such as studs and joists, insulation, vapour barrier and air barrier. They can be used for many different applications such as exterior wall, roof, floor, and foundation systems, and are all custom made for each application.

The Benefits

They were initially intended to be a temporary measure (most prefab housing was only expected to last for 10 years at most), but people remained living in their prefab homes for decades after the war had ended, and some are still standing even today.

In fact there is a prefab estate in London where the residents have lost their case against demolition – these houses were built in the 1940s and residents were happy to stay. These houses are only now being demolished to make way for contemporary housing.

How the SIPs Are Manufactured

Superior Closed Cell polyurethane Injected panels. Polyurethane sips are superior to all EPS (expanded polystyrene ) panels which will fail structurally in a fire and are less environmentally friendly, as they let off gas. Our panels are manufactured to order in our UK factory.

How They Are Built

Our Outdoor Living Rooms are delivered as a self build ‘flat-pack’ kit, complete with all the components, providing you with everything you need to construct your outdoor garden room or building. A little like flat-pack furniture, you simply need to have the right tools on hand and follow the instructions carefully!

The SIPs panels are completely self-sufficient and need little, if any, structural support. They are simply lifted into place and then joined together by a specialist glue, self-adhesive tape or foam sealant. Proper sealing is crucial in building your outdoor living room – if not it can compromise the structural integrity of the building.

Once the building is erected the basic panels need to be protected from the elements. This is done by cladding which makes the structure weatherproof.

Why We Use SIPs?

A well-built structure using SIPs will have a tighter building envelope and the walls will have higher insulating properties. This means fewer drafts and reduced operating costs.

Construction time can be reduced compared to a traditional timber frame building because SIPs work as framing, insulation and exterior sheathing, and come pre-cut from the factory to meet the needs of each individual building project. This also means fewer tradesmen are required on site.

The panels can be used as roof, walls and floor – the latter being particularly beneficial when used above an un-insulated space.

The total life-cycle cost of a building constructed from SIPs will usually be cheaper than a conventional framed one and some even achieve 40% life-time savings.

In many cases SIPs are structurally more robust than timber framed buildings but have a similar versatility for creating custom-built designs.

Building Regulations and Energy Efficiency

Under the latest revisions to the new Part L (England & Wales) Building Regulations, a minimum standard U-value is required for the thermal efficiency of a newly constructed building.

All Garden Spaces garden rooms, garden offices, lodges and buildings are designed and manufactured to exceed the U-values required under these new regulations.

What Is a U-Value?

A U-value is ‘a measure of air-to-air heat transmission (loss or gain) due to thermal conductance and the difference in indoor and outdoor temperatures, in relation to an area of material, expressed as w/m2k (Watts Per Square Metre Kelvin)’

As the U-value decreases so does the amount of heat transferred through the material, i.e. the lower the U-value, the better the level of insulation.

Required U-Values

To comply with the new Part L (England & Wales) Building Regulations building components must have U-values that are at least equivalent to the following:

Structural Insulated Panels (SIPS) are an advanced method of construction offering excellent thermal performance, light weight structural strength, and time and cost saving benefits over traditional construction methods. SIPs combine several components of conventional building, such as studs and joists, insulation, vapour barrier and air barrier. They can be used for many different applications such as exterior wall, roof, floor, and foundation systems, and are all custom made for each application.

The Benefits

- Superior Insulation – structure is completely airtight, and therefore eliminate the need and cost for cavity insulation.

- Structurally Sound – minimal support required

- Environmentally Friendly – all the materials used are biodegradable and low impact

- Extremely quick to build

- Cost effective – similar in price to traditional methods, minimal construction time, labour and materials.

- Habitable Roof Space – SIP building systems do not require roof trusses, therefore providing an additional habitable room in the roof.

- Compatible with other building systems

- Fire Safety – exceeds the Building Regulations and British Standards

They were initially intended to be a temporary measure (most prefab housing was only expected to last for 10 years at most), but people remained living in their prefab homes for decades after the war had ended, and some are still standing even today.

In fact there is a prefab estate in London where the residents have lost their case against demolition – these houses were built in the 1940s and residents were happy to stay. These houses are only now being demolished to make way for contemporary housing.

How the SIPs Are Manufactured

Superior Closed Cell polyurethane Injected panels. Polyurethane sips are superior to all EPS (expanded polystyrene ) panels which will fail structurally in a fire and are less environmentally friendly, as they let off gas. Our panels are manufactured to order in our UK factory.

How They Are Built

Our Outdoor Living Rooms are delivered as a self build ‘flat-pack’ kit, complete with all the components, providing you with everything you need to construct your outdoor garden room or building. A little like flat-pack furniture, you simply need to have the right tools on hand and follow the instructions carefully!

The SIPs panels are completely self-sufficient and need little, if any, structural support. They are simply lifted into place and then joined together by a specialist glue, self-adhesive tape or foam sealant. Proper sealing is crucial in building your outdoor living room – if not it can compromise the structural integrity of the building.

Once the building is erected the basic panels need to be protected from the elements. This is done by cladding which makes the structure weatherproof.

Why We Use SIPs?

A well-built structure using SIPs will have a tighter building envelope and the walls will have higher insulating properties. This means fewer drafts and reduced operating costs.

Construction time can be reduced compared to a traditional timber frame building because SIPs work as framing, insulation and exterior sheathing, and come pre-cut from the factory to meet the needs of each individual building project. This also means fewer tradesmen are required on site.

The panels can be used as roof, walls and floor – the latter being particularly beneficial when used above an un-insulated space.

The total life-cycle cost of a building constructed from SIPs will usually be cheaper than a conventional framed one and some even achieve 40% life-time savings.

In many cases SIPs are structurally more robust than timber framed buildings but have a similar versatility for creating custom-built designs.

Building Regulations and Energy Efficiency

Under the latest revisions to the new Part L (England & Wales) Building Regulations, a minimum standard U-value is required for the thermal efficiency of a newly constructed building.

All Garden Spaces garden rooms, garden offices, lodges and buildings are designed and manufactured to exceed the U-values required under these new regulations.

What Is a U-Value?

A U-value is ‘a measure of air-to-air heat transmission (loss or gain) due to thermal conductance and the difference in indoor and outdoor temperatures, in relation to an area of material, expressed as w/m2k (Watts Per Square Metre Kelvin)’

As the U-value decreases so does the amount of heat transferred through the material, i.e. the lower the U-value, the better the level of insulation.

Required U-Values

To comply with the new Part L (England & Wales) Building Regulations building components must have U-values that are at least equivalent to the following:

- Walls – Building Regulations Walls Minimum = 0.35 Wm2k

- Floor – Building Regulations Floor Minimum = 0.25 Wm2k

- Roof – Building Regulations Roof Minimum = 0.20 Wm2kAll of our garden buildings exceed these U-value requirements and therefore offer outstanding thermal efficiency.